Baakadaha dahaarka leh ayaa si weyn loogu isticmaalaa warshado kala duwan xooggeeda, adkeysigeeda, iyo sifooyinka xannibaadda. Walxaha caaga ah ee sida caadiga ah loo isticmaalo baakadaha dahaadhka ah waxaa ka mid ah:

| Materilas | Dhumucda | Cufnaanta (g / cm3) | WVTR (g / ㎡.24 saac) | O2 TR (cc / ㎡.24hrs) | Codsiga | Guryaha |

| NYLON | 15µ,25µ | 1.16 | 260 | 95 | Suugo, xawaash, badeecooyin budo ah, alaab jelly ah iyo alaab dareere ah. | Iska caabin heerkul hoose ah, isticmaalka dhamaadka heerkulka sare, kartida shaabadda wanaagsan iyo xajinta faakuumka wanaagsan. |

| KNY | 17µ | 1.15 | 15 | ≤10 | Hilibka la barafeeyay, Alaab leh qoyaan badan, Suugo, xawaashyo iyo maraq dareere ah. | Caqabadda qoyaanka wanaagsan, Ogsajiin sare iyo xannibaad udgoon, Heerkul hoose iyo xajin wanaagsan. |

| PET | 12µ | 1.4 | 55 | 85 | Kala duwan oo loogu talagalay cuntooyin kala duwan, badeecooyin ka yimid bariiska, cuntooyinka fudud, alaabta shiilan, shaaha & kafeega iyo maraqa. | Xannibaadda qoyaanka sarreeya iyo xannibaad oksijiin dhexdhexaad ah |

| KPET | 14µ | 1.68 | 7.55 | 7.81 | Keega moon, Keega, Cunto fudud, Alaabta habraaca, Shaaha iyo Baasto. | Caqabad qoyaan sare leh, Ogsajiin wanaagsan iyo caraf udgoon iyo iska caabin wanaagsan oo saliid ah. |

| VMPET | 12µ | 1.4 | 1.2 | 0.95 | Wax soo saar badan oo cuntooyin kala duwan ah, badeecooyin bariis laga soo saaray, cunto fudud, badeecooyin la shiilay, shaaha iyo maraqa la isku daray. | Caqabad qoyaan heer sare ah, iska caabin heerkul hooseeya oo wanaagsan, xannibaad iftiin aad u fiican iyo xannibaad udgoon oo heer sare ah. |

| OPP - Polypropylene ku jihaysan | 20µ | 0.91 | 8 | 2000 | Alaabada qalalan, buskud, popsicles iyo shokolaatada. | Caqabadda qoyaanka wanaagsan, iska caabbinta heerkulka hoose ee wanaagsan, xannibaadda iftiinka wanaagsan iyo qallafsanaanta wanaagsan. |

| CPP - Kast Polypropylene | 20-100µ | 0.91 | 10 | 38 | Alaabada qalalan, buskud, popsicles iyo shokolaatada. | Caqabadda qoyaanka wanaagsan, iska caabbinta heerkulka hoose ee wanaagsan, xannibaadda iftiinka wanaagsan iyo qallafsanaanta wanaagsan. |

| VMCPP | 25µ | 0.91 | 8 | 120 | Waxyaabo kala duwan oo cunto ah, badeecooyin bariis laga soo saaray, cunto fudud, badeecooyin la shiilay, shaaha iyo maraqa. | Caqabad qoyaan oo heer sare ah, xannibaad oksijiin sare leh, xannibaad iftiin wanaagsan iyo xannibaad saliid oo wanaagsan. |

| LLDPE | 20-200µ | 0.91-0.93 | 17 | / | Shaaha, macmacaanka, keega, lawska, cuntada xayawaanka iyo burka. | Caqabadda qoyaanka wanaagsan, caabbinta saliidda iyo xannibaadda udgoonka. |

| KOP | 23µ | 0.975 | 7 | 15 | Baakadaha cuntada sida cuntooyinka fudud, badarka, digirta, iyo cuntada xayawaanka rabaayada ah. Iska caabbinta qoyaanka iyo guryaha xannibaadda ayaa ka caawiya inay alaabtu noqdaan kuwo cusub | Xannibaadda qoyaanka sare, xannibaad oksijiin oo wanaagsan, xannibaad caraf udgoon iyo iska caabin wanaagsan oo saliid ah. |

| EVOH | 12µ | 1.13-1.21 | 100 | 0.6 | Baakadaha Raashinka, Baakadaha Vacuum, Daawooyinka, Baakadaha Cabbitaannada, Waxyaabaha la isku qurxiyo iyo Alaabooyinka Daryeelka Shakhsi ahaaneed, Alaabaha Warshadaha, Filimada Kala Duwan | Hufnaan sare. Saliida daabacan oo wanaagsan iyo xannibaad oksijiin dhexdhexaad ah. |

| Aluminium | 7µ 12µ | 2.7 | 0 | 0 | Kiishash aluminium ah ayaa caadi ahaan loo isticmaalaa in lagu xidho cunto fudud, miraha la qalajiyey, kafeega, iyo cuntooyinka xayawaanka rabaayada ah. Waxay ka ilaaliyaan waxa ku jira qoyaanka, iftiinka, iyo ogsijiinta, iyaga oo kordhinaya nolosha shelf. | Xayiraadda qoyaanka heersare ah, xannibaad iftiin aad u fiican iyo xannibaad udgoon oo heer sare ah. |

Qalabkan caagagga ah ee kala duwan ayaa inta badan lagu doortaa iyadoo lagu saleynayo shuruudaha gaarka ah ee alaabta la baakadeeyay, sida dareenka qoyaanka, baahiyaha xannibaadda, nolosha shelf, iyo tixgelinta deegaanka. Inta badan waxaa loo isticmaalaa in loo qaabeeyo sida 3 bacaha xiran, 3 dhinac oo xiran bacaha jibbaarka, Laminated Filimka Baakadaha ee Mashiinnada Atoomatiga ah, Kiishadaha Jeebka ee Taagan, Filim/Bacaha Baakadaha Mikrowaveable, Bacaha Shaabada Fin, Bacaha Madhalayska Celinta.

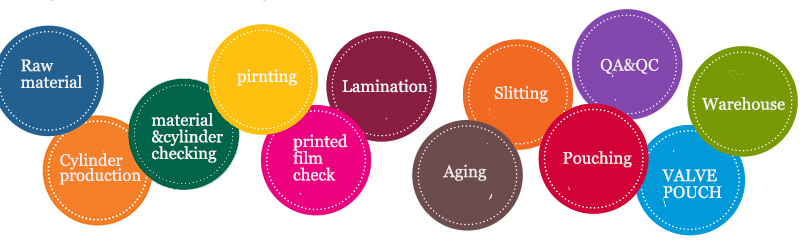

Habka boorsooyinka lamination ee dabacsan:

Waqtiga boostada: Agoosto-26-2024